FRP Pultruded Profile, Fiber Reinforced

Plastic Pultruded Profile Manufecturers, FRP

Pultruded Products Manufacturer, FRP Pultruded

Structural Shapes, Angles, Channels, I-Beams,

Wide flange beams, Round, Rectangular & Square

Tubes, Round and Square Bars, Flat Sheets,

Concrete embedment angles, Ladders, Consumer

Product Range, Gratings, Cable Trays,

Electrical Insulation Material.

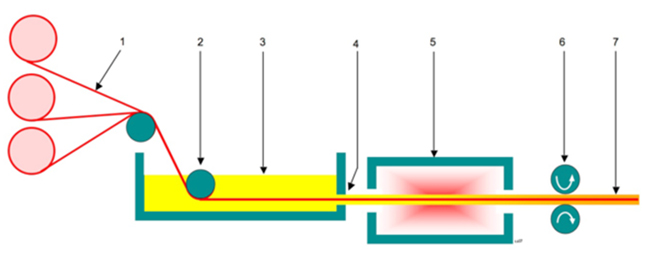

Pultrusion is a continuous process for manufacture of composite materials with constant cross-section. Reinforced fibers are pulled through a resin, possibly followed by a separate preforming system, and into a heated die, where the resin undergoes polymerization. Many resin types may be used in pultrusion including polyester, polyurethane, vinyl ester and epoxy.

Diagram of the pultrusion process

1 - Continuous roll of reinforced fibers/woven fiber mat

2 - Tension roller

3 - Resin bath

4 - Resin soaked fiber

5 - Die and heat source

6 - Pull mechanism

7 - Finished hardened fiber reinforced polymer

We are one of the most advanced Pultruders in the industry as far as our technology & quality is concerned. We offer end –to-end services involving consulting, designing, production & assembly of custom designed pultruded products for a wide range of applications.

FRP Pultruded

Profile, Fiber Reinforced Plastic Pultruded

Profile Manufecturers, FRP Pultruded Products

Manufacturer, FRP Pultruded Structural Shapes,

Angles, Channels, I-Beams, Wide flange beams,

Round, Rectangular & Square Tubes, Round and

Square Bars, Flat Sheets, Concrete embedment

angles, Ladders, Consumer Product Range,

Gratings, Cable Trays, Electrical Insulation

Material.

|

|